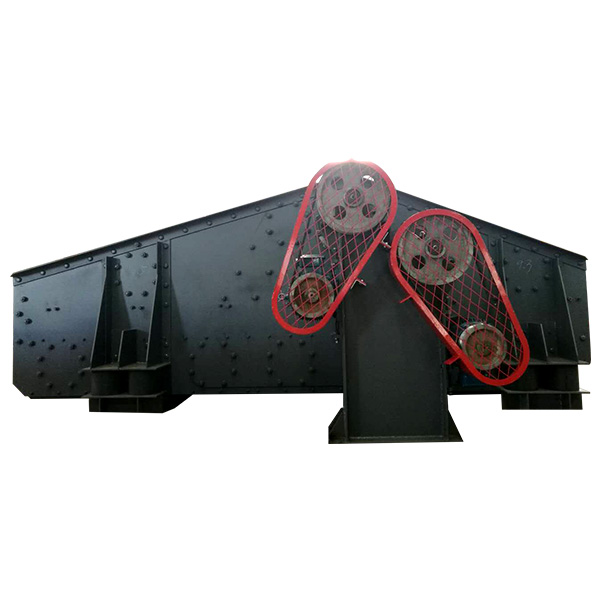

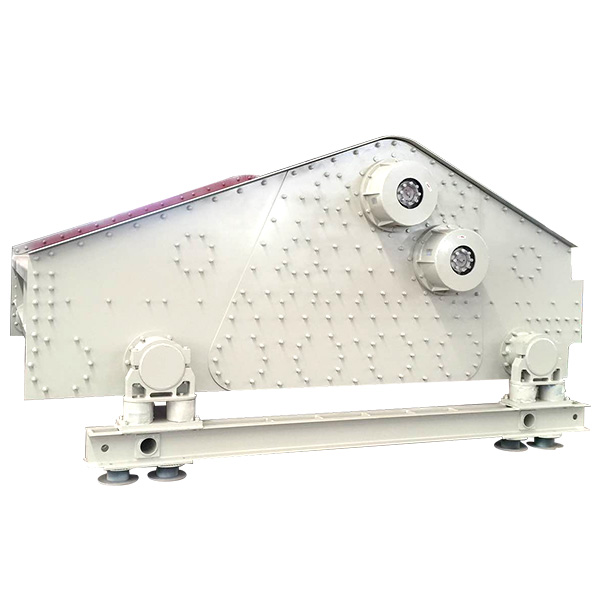

Top Quality Mine Screeen Sieve - Professional Design Powder Tumbler Circular Vibrating Screen Separator Machine – Jinte

Top Quality Mine Screeen Sieve - Professional Design Powder Tumbler Circular Vibrating Screen Separator Machine – Jinte Detail:

Company purpose:

We hold strengthening and perfecting our items and repair. At the same time, we get the job done actively to do research and progress for Professional Design Powder Tumbler Circular Vibrating Screen Separator Machine, Your help is our everlasting electricity! Warmly welcome customers at your home and abroad to go to our enterprise.

Providing the best products and solutions, the most perfect service with the most reasonable prices are our principles. We also welcome orders.Dedicated to strict quality control and thoughtful customer service, we are always available to discuss your requirements and ensure full customer satisfaction. We sincerely welcome friends to come negotiate business and start cooperation.

Product introduction:

ZSK linear vibration screen is linear movement, the whole series of 24 specifications. Coal processing, mineral processing, power generation, sugar, salt and other industrial sectors can used. ZSK linear vibrating screen is used for dry and wet screening, de-watering, dis-intermediation and de-silting of medium and fine materials.

Features & Advantages:

1. Small size, light weight, simple structure, convenient installation and easy maintenance;

2. Low noise, low energy consumption, high efficiency and low cost;

3. High screening accuracy, no dust pollution, conducive to environmental protection;

4. Can be replaced with a variety of screens, long service life;

5. Adopt block eccentric self-synchronous vibration exciter;

6. Vibrating screen can be used in other occasions with inclination.

Applications:

√ fine particle dewatering and grading

√ coal slime or tailings recovery.

Working principle and structural features:

The screen with flange type vibration exciter, from the two motor extension to reverse self-synchronous rotation, make the screen body along the straight line to do periodic reciprocating motion, so as to achieve the purpose of classification dehydration. The screen frame is connected by high-strength bolts, and the screen surface is composed of arc section and straight section. The structure is firm and durable.

Use and Maintenance:

A. starting sequence of dewatering screen: start in the direction of reverse material flow and stop in the direction of forward material flow. Avoid starting with materials, and stop after all materials are screened on the screen.

B. During the working process of the sieve, attention shall be paid to whether the operation of the sieve box is smooth or not.

C. The dewatering screen is generally installed with negative inclination Angle.

D. dust and impurities are easy to accumulate between springs, which will affect the normal operation of springs, and should be cleaned frequently.

E. often check the screen machine bolt connection, if there is a loose timely tightening.

F. The shaker bearing is lubricated with no. 3 lithium grease. Under normal conditions, lubricating oil should be added once a month and the bearing should be cleaned and inspected once a year.

|

No |

Name |

Unit |

ZSK-1231 |

ZSK-1431 |

ZSK-1837 |

ZSK-2448 |

ZSK-3645 |

|

|

1 |

Feed concentration |

% |

≥45 |

≥45 |

≥45 |

≥45 |

|

|

|

2 |

Processing capacity |

t/h |

15-19 |

15-19 |

28-33 |

60-120 |

>150 |

|

|

3 |

Screen size |

mm |

1200*3100 |

1400*3100 |

1800*3700 |

2400*4800 |

3600*4500 |

|

|

4 |

Screen size |

mm |

0.3,0.35 |

0.3,0.35 |

0.3,0.35 |

0.3,0.35 |

0.35 |

|

|

5 |

Double amplitude |

mm |

3-5 |

3-5 |

3-5 |

3-5 |

6-8 |

|

|

6 |

Vibration frequency |

Hz |

25 |

25 |

25 |

25 |

16 |

|

|

7 |

motor |

model |

Kw |

Y122M-4 |

Y132S-4 |

Y132M-4 |

Y180M-4 |

YE2-200L2-6 |

|

power |

||||||||

|

Voltage |

||||||||

|

8 |

V |

380 |

380 |

380 |

380 |

380 |

||

|

9 |

Single point maximum dynamic load |

N |

±200 |

±2500 |

±3500 |

±5000 |

52500 |

|

Product detail pictures:

Related Product Guide:

Six ways to reduce the “resonance” of the vibrating screen

We retain bettering and perfecting our goods and service. At the same time, we perform actively to do research and enhancement for Top Quality Mine Screeen Sieve - Professional Design Powder Tumbler Circular Vibrating Screen Separator Machine – Jinte , The product will supply to all over the world, such as: Senegal , Juventus , Belarus , We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

√ Since our factory belongs to the machinery industry, the equipment needs to be matched with the process.

The size, model and specifications of the product can be customized according to customer needs.

√ All products in this store are for virtual quotes and are for reference only.

The actual quotation is subject to the technical parameters and special requirements given by the customer.

√ Provide product drawing, manufacturing process and other technical services.

1. Can you offer the customized solution to my case?

Our company has a professional R & D team, and be able to customize mechanical products for you according to your needs. At the same time, our company guarantees that every product produced for you is in compliance with the national and industry standard, and no quality problems.

Please send us inquiry if u have any concerns.

2. Is the machine produced safe and reliable?

Absolutely yes. We are a company specializing in the production of machinery. We have advanced technology, excellent R & D team, superb process design and other advantages. Please believe that we can fully meet your expectations. The machines produced are in line with national and industry quality standards. Please feel free to use.

3. What is the price of the product?

The price is determined by the specifications of the product, the material, and the special requirements of the customer.

Quotation method: EXW, FOB, CIF, ect.

Payment method: T/T, L/C, ect.

Our company is committed to selling high quality products that meet your requirements at an acceptable price.

4. Why do I trade with your company?

1. Reasonable price and exquisite workmanship.

2. Professional customization, good reputation.

3. Carefree after-sales service.

4. Provide product drawing, manufacturing process and other technical services.

5. Case experience of working with many outstanding domestic and foreign companies over the years.

Regardless of whether a deal is reached or not, we sincerely welcome your letter. Learn from each other and make progress together. Maybe we can be friends of the other side. ![]()

5. Are you engineers available for overseas installation and training matters?

At the client’s request, Jinte can provide installation Technicians to supervise and assist in the assembly and commissioning of the equipment. And all the costs during the mission needs to be covered from you.

TEL: +86 15737355722

E-mail: jinte2018@126.com

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.