Hot Selling for Conveyor System - FHS arc screen – Jinte

Hot Selling for Conveyor System - FHS arc screen – Jinte Detail:

Introduction:

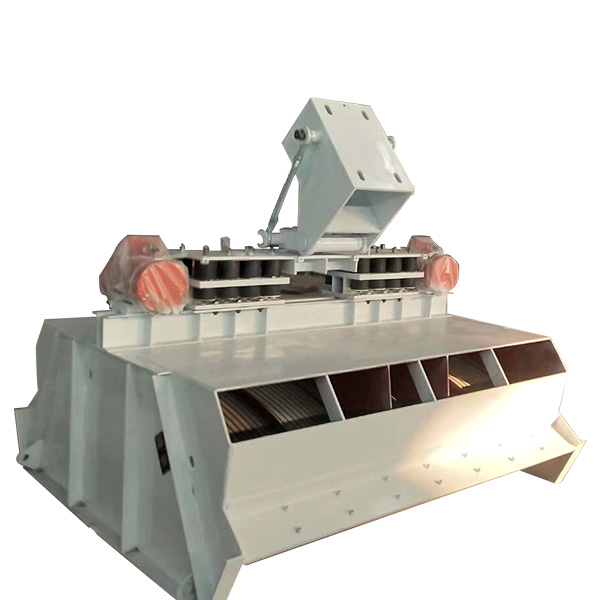

FHS arc screen is mainly used for pre-dewatering, desilting, disintermediation and grading recovery of coal slurry in coal preparation plant and ore dressing plant. Slurry realizes solid-liquid separation under the action of centrifugal force. The slurry can remove 60%-70% of the water in advance through the arc screen surface to ensure enough water spraying on the linear vibrating screen to clean the fine mud and medium adhered to the coal particles, which plays a key role in reducing product ash content and medium consumption.

FHS arc screen is made up of three parts: screen box, arc screen plate and base. The screen box adopts pivot steering structure, which can rotate 180°, and can be used in the process of using, it can not only extend the service life of stainless steel screen plate, but also improve the effect of dewatering, desilting and disintermedium.

Features & Advantages:

1. The curved screen surface and the screen frame adopt the pivotal special structure, which can rotate 180 degrees and extend the service life of the screen surface.

|

Model |

Screen Width (mm) |

Processing Capacity |

Sieve Pore(mm) |

Radius (mm) |

Wrap Angle(°) |

Screen Strip Width (mm) |

Weight(Kg) |

|

(m³/h) |

|||||||

|

FHS-09201 |

920 |

50-110 |

0.4-1.0 |

1016 |

45 |

2.38 |

750 |

|

FHS-1220I |

1220 |

70-145 |

0.4-1.0 |

1016 |

45 |

2.38 |

880 |

|

FHS-15201 |

1520 |

85-180 |

0.4-1.0 |

1016 |

45 |

2.38 |

1090 |

|

FHS-1820I |

1820 |

105-216 |

0.4-1.0 |

1016 |

45 |

2.38 |

1200 |

|

FHS-2120I |

2120 |

122-250 |

0.4-1.0 |

1016 |

45 |

2.38 |

1320 |

|

FHS-2420I |

2420 |

140-285 |

0.4-1.0 |

1016 |

45 |

2.38 |

1450 |

|

FHS-3000I |

3000 |

175-355 |

0.4-1.0 |

1016 |

45 |

2.38 |

1780 |

|

FHS-3200I |

3200 |

190-375 |

0.4-1.0 |

1016 |

45 |

2.38 |

1920 |

|

FHS-0920 II |

920 |

70-140 |

0.4-1.0 |

1016 |

60 |

2.38 |

850 |

|

FHS-1220 II |

1220 |

95-190 |

0.4-1.0 |

1016 |

60 |

2.38 |

1000 |

|

FHS-1520 II |

1520 |

119-240 |

0.4-1.0 |

1016 |

60 |

2.38 |

1120 |

|

FHS-1820 II |

1820 |

143-288 |

0.4-1.0 |

1016 |

60 |

2.38 |

1300 |

|

FHS-2120 II |

2120 |

167-336 |

0.4-1.0 |

1016 |

60 |

2.38 |

1400 |

|

FHS-2420 II |

2420 |

191-336 |

0.4-1.0 |

1016 |

60 |

2.38 |

1520 |

|

FHS-3000 II |

3000 |

240-430 |

0.4-1.0 |

1016 |

60 |

2.38 |

1900 |

|

FHS-3200 II |

3200 |

280-460 |

0.4-1.0 |

1016 |

60 |

2.38 |

2120 |

|

FHS-0920 III |

920 |

85-180 |

0.4-1.0 |

2032 |

45 |

2.38 |

950 |

|

FHS-1220 III |

1220 |

115-240 |

0.4-1.0 |

2032 |

45 |

2.38 |

1120 |

|

FHS-1520 III |

1520 |

145-300 |

0.4-1.0 |

2032 |

45 |

2.38 |

1230 |

|

FHS-1820 III |

1820 |

175-360 |

0.4-1.0 |

2032 |

45 |

2.38 |

1430 |

|

FHS-2120 III |

2120 |

205-420 |

0.4-1.0 |

2032 |

45 |

2.38 |

1530 |

|

FHS-2420 III |

2420 |

235-480 |

0.4-1.0 |

2032 |

45 |

2.38 |

1650 |

|

FHS-3000 III |

3000 |

295-600 |

0.4-1.0 |

2032 |

45 |

2.38 |

2050 |

|

FHS-3200 III |

3200 |

330-650 |

0.4-1.0 |

2032 |

45 |

2.38 |

2240 |

|

FHS-0920 IV |

920 |

115-240 |

0.4-1.0 |

2032 |

60 |

2.38 |

1050 |

|

FHS-1220 IV |

1220 |

156-320 |

0.4-1.0 |

2032 |

60 |

2.38 |

1120 |

|

FHS-1520 IV |

1520 |

195-400 |

0.4-1.0 |

2032 |

60 |

2.38 |

1310 |

|

FHS-1820 IV |

1820 |

234-480 |

0.4-1.0 |

2032 |

60 |

2.38 |

1500 |

|

FHS-2120 IV |

2120 |

272-560 |

0.4-1.0 |

2032 |

60 |

2.38 |

1640 |

|

FHS-2420 IV |

2420 |

312-560 |

0.4-1.0 |

2032 |

60 |

2.38 |

1780 |

|

FHS-3000 IV |

3000 |

392-720 |

0.4-1.0 |

2032 |

60 |

2.38 |

2150 |

|

FHS-3200 IV |

3200 |

430-800 |

0.4-1.0 |

2032 |

60 |

2.38 |

2350 |

Product detail pictures:

Related Product Guide:

Six ways to reduce the “resonance” of the vibrating screen

We keep on with our business spirit of "Quality, Performance, Innovation and Integrity". We goal to create much more worth for our customers with our rich resources, state-of-the-art machinery, experienced workers and exceptional providers for Hot Selling for Conveyor System - FHS arc screen – Jinte , The product will supply to all over the world, such as: Slovenia , Vietnam , Swansea , We've more than 10 years exported experience and our products and solutions have expored more than 30 countries around the word . We always hold the service tenet Client first,Quality first in our mind,and are strict with product quality. Welcome your visiting!

√ Since our factory belongs to the machinery industry, the equipment needs to be matched with the process.

The size, model and specifications of the product can be customized according to customer needs.

√ All products in this store are for virtual quotes and are for reference only.

The actual quotation is subject to the technical parameters and special requirements given by the customer.

√ Provide product drawing, manufacturing process and other technical services.

1. Can you offer the customized solution to my case?

Our company has a professional R & D team, and be able to customize mechanical products for you according to your needs. At the same time, our company guarantees that every product produced for you is in compliance with the national and industry standard, and no quality problems.

Please send us inquiry if u have any concerns.

2. Is the machine produced safe and reliable?

Absolutely yes. We are a company specializing in the production of machinery. We have advanced technology, excellent R & D team, superb process design and other advantages. Please believe that we can fully meet your expectations. The machines produced are in line with national and industry quality standards. Please feel free to use.

3. What is the price of the product?

The price is determined by the specifications of the product, the material, and the special requirements of the customer.

Quotation method: EXW, FOB, CIF, ect.

Payment method: T/T, L/C, ect.

Our company is committed to selling high quality products that meet your requirements at an acceptable price.

4. Why do I trade with your company?

1. Reasonable price and exquisite workmanship.

2. Professional customization, good reputation.

3. Carefree after-sales service.

4. Provide product drawing, manufacturing process and other technical services.

5. Case experience of working with many outstanding domestic and foreign companies over the years.

Regardless of whether a deal is reached or not, we sincerely welcome your letter. Learn from each other and make progress together. Maybe we can be friends of the other side. ![]()

5. Are you engineers available for overseas installation and training matters?

At the client’s request, Jinte can provide installation Technicians to supervise and assist in the assembly and commissioning of the equipment. And all the costs during the mission needs to be covered from you.

TEL: +86 15737355722

E-mail: jinte2018@126.com

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!