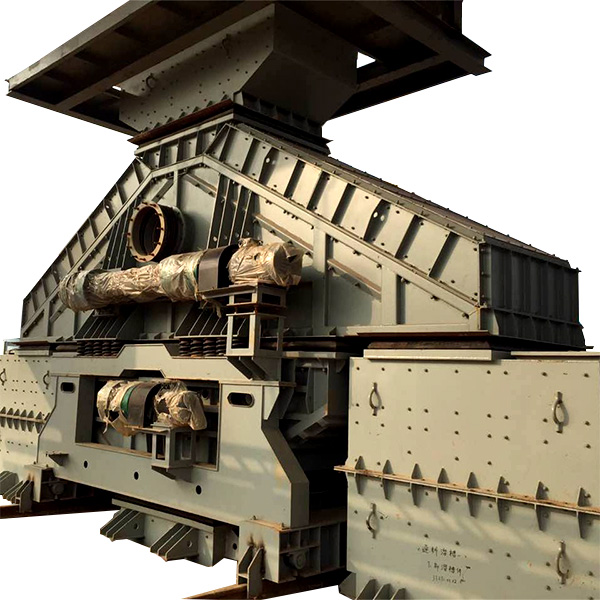

Chinese wholesale Linear Vibrating Feeder - JFSS series sintering environmental protection screen – Jinte

Chinese wholesale Linear Vibrating Feeder - JFSS series sintering environmental protection screen – Jinte Detail:

Introduction:

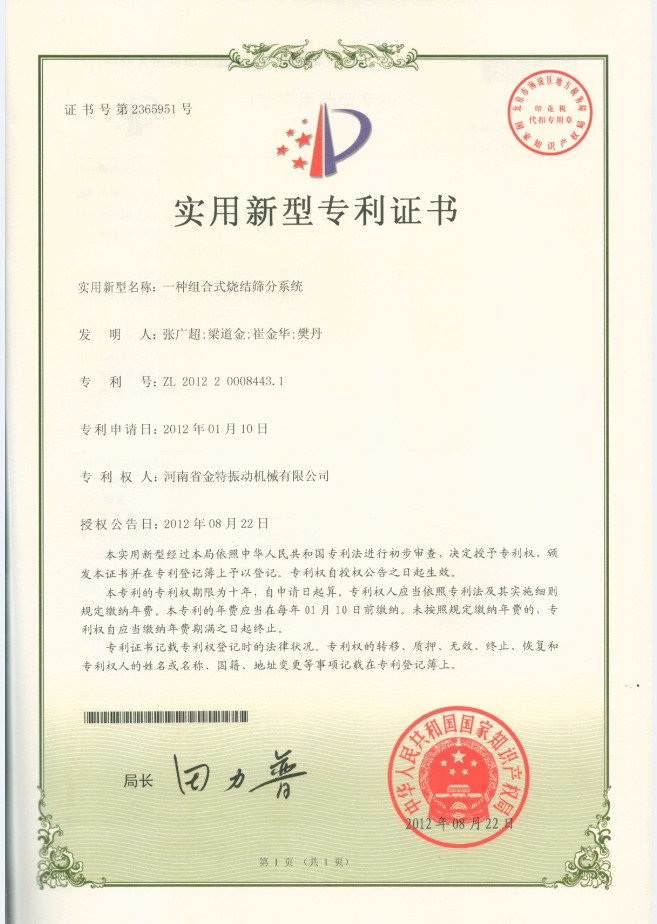

JFSS series new composite vibration screen is a new type of energy-saving composite vibration equipment independently developed by our company, which was granted the national patent in 2009. The screen machine is mainly used in blast furnace trough, sintering plant, raw material plant, coal, mining plant, ect.

Construction:

1. screen plate

2. feed port

3. material export on the screen

4. material export under the screen

5. screen box

6. sealing cover

7. dust removal port

8. vibration damping device

9. vibration source.

Features & advantages:

1. Be arranged back-to-back in the sieve box, with adult font arrangement and compact structure,which can effectively reduce the floor space and make reasonable use of space

2. Adopt rod and bar structure and be designed with self-cleaning device. High opening rate of sieve hole, not easy to block, high screening efficiency;

3. A sealing cover above the sieve box to make the screening work in a fully sealed state, which can effectively prevent dust generated by the screening from flying everywhere;

4. Equipped with dust removal port, which can absorb the dust generated in the work of the vibrating screen, greatly reduce the dust caused by screening materials, and improve the dust removal effect.

5. The sluice gate is designed at the feed inlet, which can effectively control the material flow, adjust the material flow amount on both sides of the screen plate, and make the material distribution balance.

6. The screen box can be supported on a fixed base, or on a walking bottom frame with walking wheel and rail clamp.

Technical Parameters:

|

JFSS Series Sintered Environmental Protection Screen |

|||||

|

Sintering Machine (㎡) |

Matched Vibrating Screen (Model) |

Processing Capacity (t/h) |

Quantity (Set) |

Blanking Granularity (mm ) |

Remarks |

|

|

|

|

|

|

|

|

90 |

JFSS105*600 Sintering Primary Sieve |

400 |

2 |

10 |

Open One, Get One Ready |

|

JFSS105*600 |

220 |

2 |

5 |

Open One, Get One Ready |

|

|

JFSS105*600 Sintering Tertiary Sieve |

220 |

2 |

20 |

Open One, Get One Ready |

|

|

180 |

2JFSS125*700-II Sintering Primary And Secondary Sieves |

500 |

2 |

20、10 |

Open One, Get One Ready |

|

JFSS125*600-I丨Sintering Tertiary Sieve |

300 |

2 |

5 |

Open One, Get One Ready |

|

|

2*180 |

2JFSS125*600-IV Sintering Primary And Secondary Sieves |

650 |

3 |

20、10 |

Open One, Get One Ready |

|

2JFSS125*600-IV Sintering Secondary Sieve |

400 |

3 |

5 |

Open One, Get One Ready |

|

|

265 |

2JFSS150*700-II Sintering Primary And Secondary Sieves |

700 |

2 |

20、10 |

Open One, Get One Ready |

|

JFSS150X600-I丨Sintering Secondary Sieve |

350 |

2 |

5 |

Open One, Get One Ready |

|

|

2*265 |

2JFSS150*700-IV Sintering Primary And Secondary Sieves |

750 |

3 |

20、10 |

Open One, Get One Ready |

|

2JFSS150*600-IV Sintering Secondary Sieve |

350 |

3 |

5 |

Open One, Get One Ready |

|

|

360 |

2JFSS150*700-MSintering Primary And Secondary Sieves |

890 |

2 |

20、10 |

Open One, Get One Ready |

|

2JFSS150*600-I丨Sintering Secondary Sieve |

500 |

2 |

5 |

Open One, Get One Ready |

|

|

2*360 |

2JFSS150*700-IV Sintering Primary And Secondary Sieves |

950 |

2 |

20、10 |

Open One, Get One Ready |

|

2JFSS150*600-IV Sintering Secondary Sieve |

700 |

2 |

5 |

Open One, Get One Ready |

|

|

450 |

2JFSS185*700-II Sintering Primary And Secondary Sieves |

1050 |

2 |

20、10 |

Open One, Get One Ready |

|

2JFSS185*600-M Sintering Secondary Sieve |

700 |

2 |

5 |

Open One, Get One Ready |

|

|

2*450 |

2JFSS185*700-IV Sintering Primary And Secondary Ssieves |

1050 |

4 |

20、10 |

Open Three And Prepare One |

|

2 J FSS185*600- IV Sintering Secondary Sieve |

700 |

4 |

5 |

Open Two And Prepare One |

|

|

500 |

2JFSS200*700-II Sintering Primary And Secondary Sieves |

1150 |

2 |

20、10 |

Open One, Get One Ready |

|

2JFSS200*600-I丨Sintering Secondary Sieve |

800 |

2 |

5 |

Open One, Get One Ready |

|

|

2*500 |

2JFSS200*700-IVSintering Primary And Secondary Sieves |

1050 |

4 |

20、10 |

Open Three And Prepare One |

|

2JFSS200*600-IV Sintering Secondary Sieve |

700 |

4 |

5 |

Open three and prepare One |

|

Product detail pictures:

Related Product Guide:

Six ways to reduce the “resonance” of the vibrating screen

The really abundant projects administration experiences and just one to one particular provider model make the substantial importance of organization communication and our easy understanding of your expectations for Chinese wholesale Linear Vibrating Feeder - JFSS series sintering environmental protection screen – Jinte , The product will supply to all over the world, such as: belarus , Barcelona , UK , We set "be a creditable practitioner to achieve the continuous development and innovation" as our motto. We would like to share our experience with friends at home and abroad, as a way to create a bigger cake with our joint efforts. We have several experienced R & D persons and we welcome OEM orders.

√ Since our factory belongs to the machinery industry, the equipment needs to be matched with the process.

The size, model and specifications of the product can be customized according to customer needs.

√ All products in this store are for virtual quotes and are for reference only.

The actual quotation is subject to the technical parameters and special requirements given by the customer.

√ Provide product drawing, manufacturing process and other technical services.

1. Can you offer the customized solution to my case?

Our company has a professional R & D team, and be able to customize mechanical products for you according to your needs. At the same time, our company guarantees that every product produced for you is in compliance with the national and industry standard, and no quality problems.

Please send us inquiry if u have any concerns.

2. Is the machine produced safe and reliable?

Absolutely yes. We are a company specializing in the production of machinery. We have advanced technology, excellent R & D team, superb process design and other advantages. Please believe that we can fully meet your expectations. The machines produced are in line with national and industry quality standards. Please feel free to use.

3. What is the price of the product?

The price is determined by the specifications of the product, the material, and the special requirements of the customer.

Quotation method: EXW, FOB, CIF, ect.

Payment method: T/T, L/C, ect.

Our company is committed to selling high quality products that meet your requirements at an acceptable price.

4. Why do I trade with your company?

1. Reasonable price and exquisite workmanship.

2. Professional customization, good reputation.

3. Carefree after-sales service.

4. Provide product drawing, manufacturing process and other technical services.

5. Case experience of working with many outstanding domestic and foreign companies over the years.

Regardless of whether a deal is reached or not, we sincerely welcome your letter. Learn from each other and make progress together. Maybe we can be friends of the other side. ![]()

5. Are you engineers available for overseas installation and training matters?

At the client’s request, Jinte can provide installation Technicians to supervise and assist in the assembly and commissioning of the equipment. And all the costs during the mission needs to be covered from you.

TEL: +86 15737355722

E-mail: jinte2018@126.com

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.