Iboju Apapo JFHS pẹlu Deki Pupọ

Iboju Apapo JFHS pẹlu Deki Pupọ

Àwọn Ẹ̀yà ara àti Àwọn Àǹfààní

Ti o ba fẹ wo oju opo wẹẹbu ifijiṣẹ, jọwọ tẹ ibi:https://www.hnjinte.com/news/the-unit-composite-screen-of-the-lime-kiln-project-in-shenglong-guangxi-has-been-shipped

Ìlànà Ìmọ̀-ẹ̀rọ:

| Àwòṣe | Agbára Mọ́tò | Ìtóbi | Ìwọ̀n ìfúnni | Ihò Sieve | Agbara Iṣiṣẹ | Awọn Iwọn Ita |

|

| (Kw) | (mm) | (mm) | (mm) | (t/h) | Gígùn * Fífẹ̀ * Gíga (mm) |

| JFHS1536 | 2 * 4 | 6-15 | ≤500 | 3-50 | 350 |

|

| JFHS1545 | 2 * 7.5 | ⼜80 | 3-50 | 100 |

| |

| JFHS1550 | 4 * 3.0 | 0-150 | 5-50 | 100-250 | 5300*3600*4000 | |

| JFHS1840 |

| 0-150 | 5-50 |

|

| |

| JFHS1850 | 4*4.0 | 0-150 | 5-50 | 150-200 | 5300*3900*4000 | |

| JFHS2050 | 6*5.5 | 0-150 | 5-50 | 220-280 | 5300*4100*4000 | |

| JFHS2250 | 4 * 7.5 | 0-150 | 5-50 | 300-400 | 5300*4400*4200 | |

| JFHS2550 | 4 * 7.5 | 0-150 | 5-50 | 350-650 | 5300*4800*4200 | |

| JFHS2575 | 6*7.5 | 0-150 | 5-80 | 550-900 | 8000*4800*5400 | |

| JFHS25100 | 8*15 | 0-150 | 5-80 | 550-1200 | 10000*4800*5400 | |

| JFHS25125 | 10*7.5 | 0-150 | 5-80 | 550-1400 | 12500*4800*5700 |

Ilé iṣẹ́ àti ẹgbẹ́

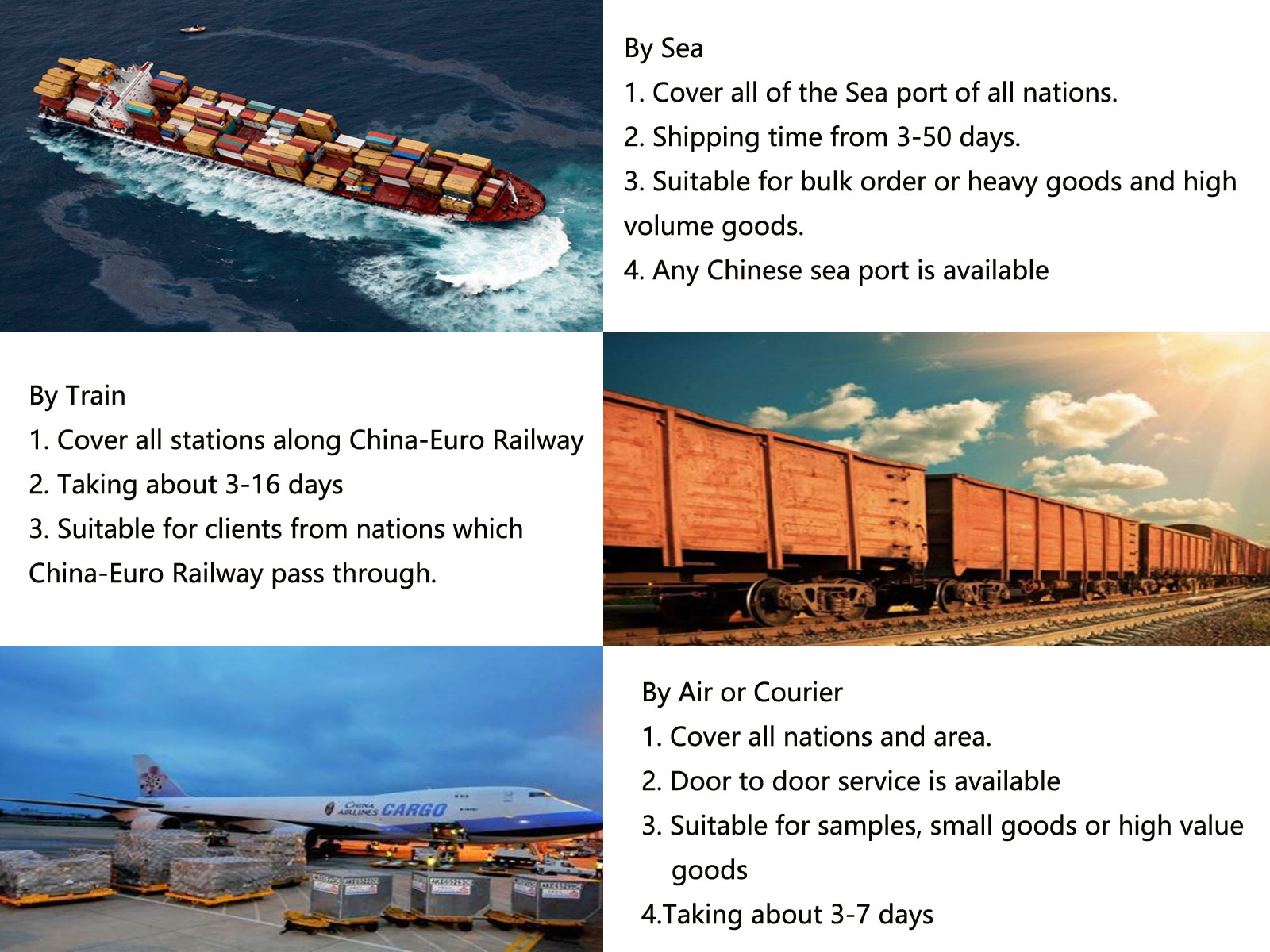

Ifijiṣẹ

√Nítorí pé ilé iṣẹ́ wa jẹ́ ti ilé iṣẹ́ ẹ̀rọ, ó yẹ kí a bá ìlànà náà mu.

Iwọn, awoṣe ati awọn alaye pato ti ọja naa le ṣe adani gẹgẹbi awọn aini alabara.

√Gbogbo awọn ọja ninu ile itaja yii wa fun awọn agbasọ ọrọ foju ati pe wọn wa fun itọkasi nikan.

Ìtumọ̀ gidi nikoko-ọrọsi awọn paramita imọ-ẹrọ ati awọn ibeere pataki ti alabara fun.

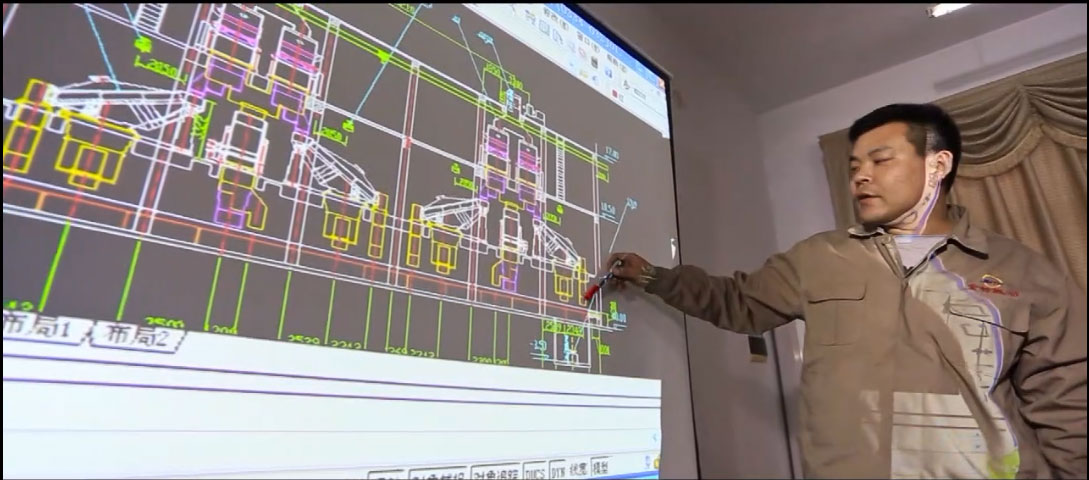

√Pese iyaworan ọja, ilana iṣelọpọ ati awọn iṣẹ imọ-ẹrọ miiran.

1. Ṣé o lè fún mi ní ojútùú tí a ṣe àdáni sí ọ̀ràn mi?

Ilé-iṣẹ́ wa ní ẹgbẹ́ ìmọ̀-ẹ̀rọ àti ìmọ̀ ẹ̀rọ tó ń ṣiṣẹ́, wọ́n sì lè ṣe àtúnṣe àwọn ọjà ẹ̀rọ fún ọ gẹ́gẹ́ bí o ṣe fẹ́. Ní àkókò kan náà, ilé-iṣẹ́ wa ń ṣe ìdánilójú pé gbogbo ọjà tí a ṣe fún ọ wà ní ìbámu pẹ̀lú ìlànà orílẹ̀-èdè àti ti ilé-iṣẹ́, kò sì sí ìṣòro dídára.

Jọwọ fi ibeere ranṣẹ si wa ti o ba ni awọn ifiyesi eyikeyi.

2. Ṣé ẹ̀rọ náà wà ní ààbò tí ó sì ṣeé gbẹ́kẹ̀lé?

Bẹ́ẹ̀ ni. Ilé-iṣẹ́ kan tí a mọ̀ sí iṣẹ́ ẹ̀rọ ni wá. A ní ìmọ̀ ẹ̀rọ tó ti gòkè àgbà, ẹgbẹ́ R & D tó dára, apẹ̀rẹ̀ iṣẹ́ tó dára àti àwọn àǹfààní míì. Jọ̀wọ́ gbàgbọ́ pé a lè mú gbogbo ohun tí ẹ ń retí ṣẹ. Àwọn ẹ̀rọ tí a ṣe bá àwọn ìlànà dídára orílẹ̀-èdè àti ti ilé-iṣẹ́ mu. Jọ̀wọ́ má ṣe lọ́ tìkọ̀ láti lò ó.

3. Iye owo ọja naa melo ni?

Iye owo naa ni a pinnu nipasẹ awọn pato ti ọja naa, awọn ohun elo naa, ati awọn ibeere pataki ti alabara.

Ọ̀nà ìfọ̀rọ̀wérọ̀: EXW, FOB, CIF, àti bẹ́ẹ̀ bẹ́ẹ̀ lọ.

Ọ̀nà ìsanwó: T/T, L/C, àti bẹ́ẹ̀ bẹ́ẹ̀ lọ.

Ilé-iṣẹ́ wa ti pinnu lati ta awọn ọja didara giga ti o ba awọn ibeere rẹ mu ni idiyele ti o tọ.

4. Kí ló dé tí mo fi ń ṣe ìṣòwò pẹ̀lú ilé-iṣẹ́ yín?

1. Owó tó bófin mu àti iṣẹ́ ọwọ́ tó dára.

2. Ṣíṣe àtúnṣe ọ̀jọ̀gbọ́n, orúkọ rere.

3. Iṣẹ́ àṣekára lẹ́yìn títà ọjà.

4. Pese iyaworan ọja, ilana iṣelọpọ ati awọn iṣẹ imọ-ẹrọ miiran.

5. Ìrírí iṣẹ́ pẹ̀lú ọ̀pọ̀lọpọ̀ ilé-iṣẹ́ abẹ́lé àti ti òkèèrè tó tayọ̀ láti ọ̀pọ̀ ọdún sẹ́yìn.

Yálà a ti dé àdéhùn tàbí bẹ́ẹ̀ kọ́, a fi tọkàntọkàn gba lẹ́tà yín. Ẹ kọ́ ẹ̀kọ́ lára ara yín kí ẹ sì jọ tẹ̀síwájú. Bóyá a lè jẹ́ ọ̀rẹ́ ẹ̀gbẹ́ kejì.. ![]()

5. Ṣé ẹ̀yin onímọ̀ ẹ̀rọ wà fún fífi sori ẹrọ àti ìdánilẹ́kọ̀ọ́ ní òkè òkun?

Ní ìbéèrè oníbàárà, Jinte lè pèsè àwọn Onímọ̀-ẹ̀rọ ìfisílé láti ṣe àbójútó àti láti ran àwọn ènìyàn lọ́wọ́ nínú ìtòjọ àti fífi àwọn ohun èlò náà sílẹ̀. Gbogbo owó tí a ná nígbà iṣẹ́ náà gbọ́dọ̀ jẹ́ ti yín.

Foonu: +86 15737355722

E-mail: jinte2018@126.com