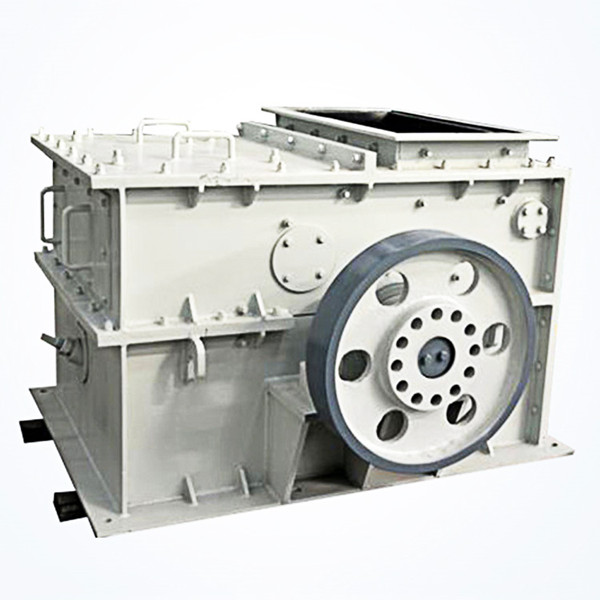

Ngenxa yendawo yokusebenza enzima ye-crusher kanye nomthamo wokuthwala umfutho ophezulu, kubalulekile ukuthi umsebenzisi azi kahle izindlela zokuxazulula izinkinga zamaphutha avamile e-crusher. Lapha, sizokwethula izindlela ezintathu ezinkulu zokuxazulula izinkinga zomshini ezivame ukusetshenziswa yi-crusher.

Ukwehluleka okukhulu okuthathu kwe-crusher

1, ukuxazulula izinkinga

2, ukuxazulula izinkinga zokwehluleka kwe-shaft

3, ukulungisa, ukuxazulula inkinga ye-rotor core

一, Umphini ojikelezayo ujikeleziswa yi-bearing support, ngakho-ke uyingxenye yomthwalo osindayo kanye nengxenye egqokekayo.

(1) Ukuhlolwa kwamaphutha

1. Hlola ngesikhathi sokusebenza: Uma i-rolling bearing ishoda ngamafutha, uzozwa umsindo “wamathambo ethambo”; uma uzwa umsindo “wesiqu” esingaqhubeki, indandatho yensimbi ye-bearing ingase iphuke. Uma i-bearing ixubene nesihlabathi kanye nezinye izinsalela noma izingxenye ze-bearing zigugile kancane, kuphuma umsindo omncane.

2. Ukuhlolwa ngemva kokudilizwa: Hlola umzimba we-rolling bearing bearing, indandatho yensimbi yangaphakathi neyangaphandle ukuthi ayilimele yini, ukugqwala, isibazi, njll., bese ucindezela indandatho yangaphakathi ye-bearing bese ubamba i-bearing, bese ucindezela indandatho yangaphandle ngesinye isandla. Uma i-bearing ilungile, indandatho yensimbi yangaphandle kufanele ijikeleze kahle, akukho ukudlidliza okusobala kanye nesenzakalo esibambekile ngesikhathi sokujikeleza, futhi indandatho yensimbi yangaphandle ayihlehli ngemva kokuma. Ngaphandle kwalokho i-bearing ayisakwazi ukusetshenziswa. Isandla sobunxele sinamathele endandatho yangaphandle, kanti isandla sokudla sicindezela indandatho yensimbi yangaphakathi bese siyisunduza siye kolunye uhlangothi. Uma izwakala ikhululekile lapho icindezelwa, igugile kakhulu.

(2) Ukulungisa izinkinga: Amabala okugqwala ebusweni bangaphandle be-bearing angasulwa nge-sandpaper bese ehlanzwa ngophethiloli; noma uma i-bearing inemifantu, amasongo angaphakathi nangaphandle ephukile noma i-bearing igugile kakhulu, i-bearing entsha kufanele ishintshwe. Uma ushintsha i-bearing entsha, sebenzisa i-bearing efanayo nemodeli yokuqala.

Ukuxazulula izinkinga zokwehluleka kweshaft

(1) Ukuguga kobubanzi beshaft: Uma ububanzi beshaft bungagqokwanga, ungqimba lwe-chrome lungafakwa kububanzi beshaft bese lugaywa ngosayizi odingekayo; uma kukhona ukuguga okwengeziwe, lungavela kububanzi beshaft bese lunqunywa ku-lathe; Uma ububanzi beshaft budakwe kakhulu, i-2-3 nn nayo ivulwa kububanzi beshaft, bese kubekwa umkhono, ukushisa kubekwa kububanzi beshaft, bese kuphendulwa kusayizi odingekayo.

(2) Ukujika nokugoba: Uma i-crusher ingagobi kakhulu, ingalungiswa ngokugaya ububanzi bomgodi kanye nendandatho yokushelela; uma ukugoba kungaphezu kuka-0.2mm, i-shaft ingafakwa ngaphansi kokucindezela bese ingcindezi ilungiswa endaweni yokugoba. Ubuso bomgodi obulungisiwe bupholishwa nge-lathe; uma ukugoba kukhulu kakhulu, kudingeka i-shaft entsha.

Ukuxazulula izinkinga ze-rotor core okulungisiwe

(1) I-crusher bearing igugile kakhulu noma ayifani, okwenza i-stator ne-rotor zikhuhle, okubangela umonakalo ebusweni be-iron core, okubangela i-short circuit phakathi kwamashidi ensimbi e-silicon futhi kwandisa ukulahlekelwa kwensimbi kwemoto, okuwukukhuphuka kwezinga lokushisa ngokweqile kwemoto. Ngalesi sikhathi, ithuluzi lisetshenziselwa ukususa i-burr, ishidi lensimbi ye-silicon liyafinyezwa, upende wokuvikela ugesi uyasetshenziswa ngemva kokuhlanza, bese ukushisa komiswa.

(2) Uma ukugoqa okudala kususwa, amandla aba makhulu kakhulu, kangangokuthi isikhala samazinyo siyagobeka futhi sivuleke ngaphandle. Ngalesi sikhathi, amathuluzi anjenge-pliers enekhala lenaliti kanye nama-hoe okhuni asetshenziselwa ukubopha kabusha ama-gullet, futhi izinto eziqinile zokuvikela njengephepha eliluhlaza noma ukhuni lwerabha zengezwa phakathi kwamashidi ensimbi e-silicon aqhekekile angakahlelwa kabusha kahle.

(3) Ubuso bomgogodla buyagqwala ngenxa yomswakama nezinye izizathu. Kuleli qophelo, kudingeka kuhlanzwe futhi kuhlanzwe, bese kufakwa i-varnish evikelayo.

(4) Ukushiswa ngokushisa okukhulu komsele oyinhloko noma izinyo elizungeze isisekelo seqembu. Idiphozithi ingasuswa ngethuluzi elinjengesiseyili noma isikrufu bese yomiswa nge-varnish evikelayo.

(5) Inhlanganisela phakathi kwe-iron core kanye ne-base ikhululekile, futhi i-set screw yokuqala ingaqiniswa. Uma i-positioning screw yehluleka, phinda ubhoboze imbobo ye-positioning esisekelweni bese uthinta ucingo ukuze uqinise i-set screw.

Uma unenkinga ngemishini, sicela ungangabazi ukusithinta. Nansi isayithi lethu lomshado:https://www.hnjinte.com

Isikhathi sokuthunyelwe: Septhemba-04-2019